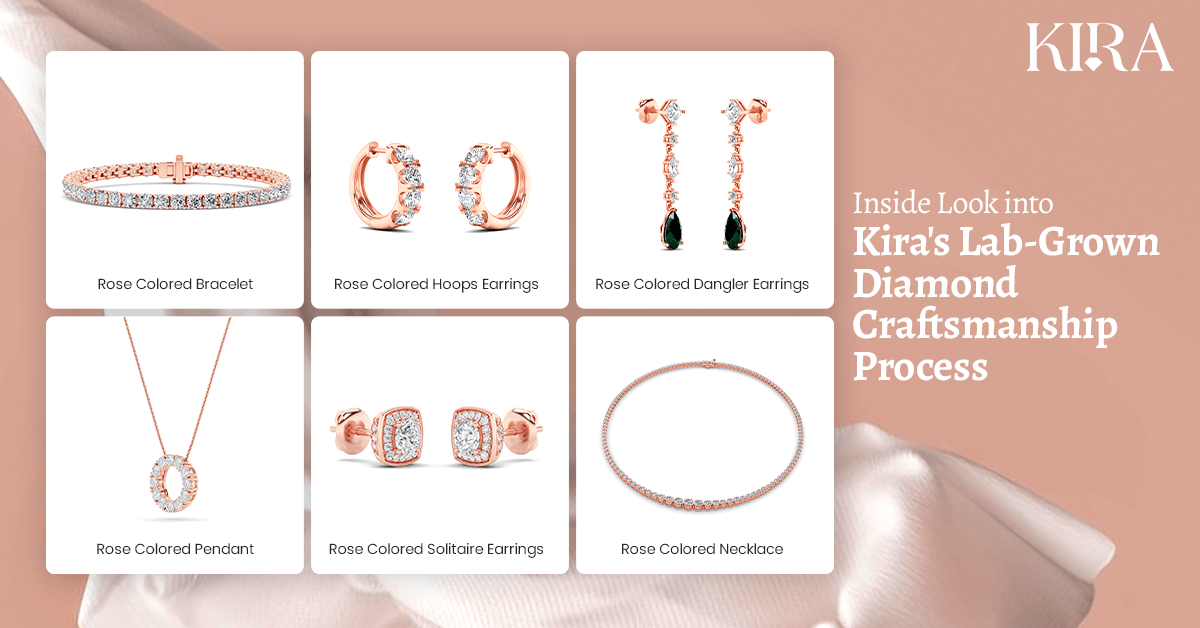

Inside Look into Kira’s Lab-Grown Diamond Craftsmanship Process

When we think of diamonds, images of brilliance, luxury, and rare beauty often come to mind. But have you ever wondered what goes on behind the scenes to create these stunning, timeless pieces in a lab setting? Welcome to Kira, the world’s largest lab-grown diamond manufacturer, where science meets artistry at its finest.

With our state-of-the-art facility in Surat, India, and a robust inventory in New York City, we’re redefining the diamond industry with sustainable, eco-friendly practices that sparkle as brightly as our creations.

The world is shifting. The demand for ethically sourced, environmentally responsible products is stronger than ever, and the diamond industry is no exception. Kira is proud to be at the forefront of this change, powered by our commitment to renewable energy and an unwavering focus on quality.

In this blog, we’ll take you on an exclusive journey through Kira’s diamond craftsmanship process—from the very seed to the finished product that graces jewelry showcases worldwide.

The Seed-to-Sparkle Journey of Kira Diamonds

Step 1: Cultivating the Diamond Seed

Everything starts with a seed. No, not the kind you plant in the ground, but a tiny fragment of crystal that acts as the foundational building block of a diamond. At Kira, this is where the magic begins. The initial stage of creating a lab-grown diamond involves selecting and preparing this diamond “seed.”

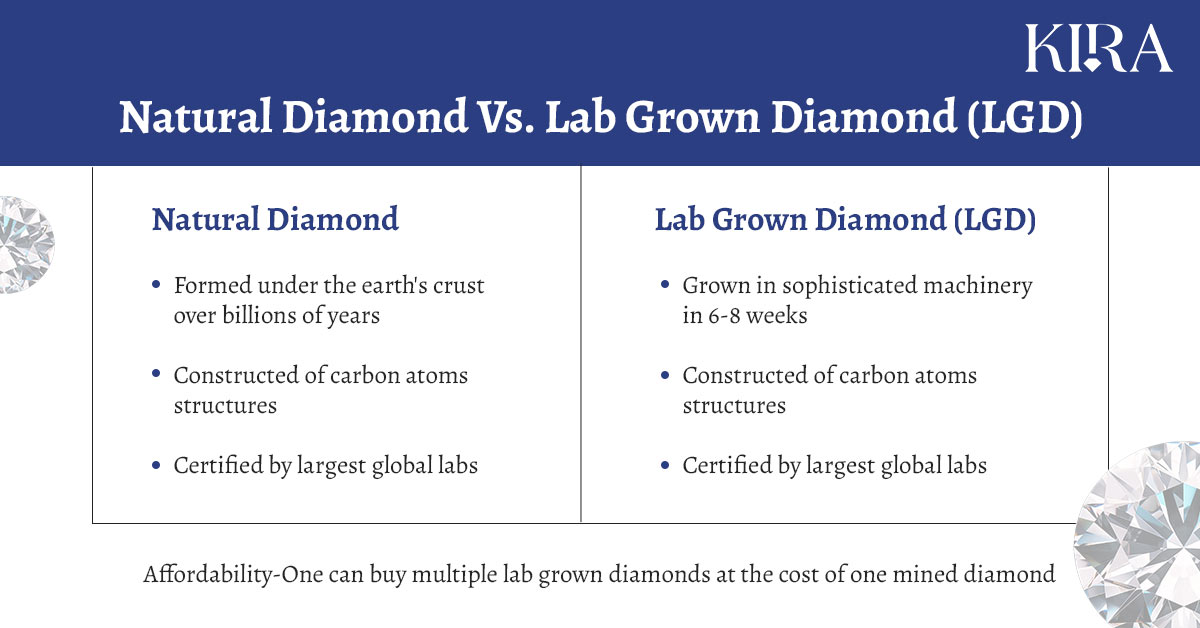

Through our advanced high-pressure process, we replicate the natural conditions found miles beneath the earth’s surface. Imagine temperatures hotter than molten lava and pressures so intense they could crush a skyscraper. This controlled environment is where carbon atoms arrange themselves meticulously around the seed, forming a diamond crystal. Our team’s precision and dedication to quality mean that each seed is nurtured to become the starting point for a flawless gem.

Step 2: Growing the Diamond in a Controlled Environment

Now, let’s talk about chemical vapor deposition (CVD) — our favorite way of nurturing diamonds. This process sounds complex (and trust us, it is), but at its core, it’s a brilliant dance of science. We place the diamond seed in a chamber where carbon-rich gases are introduced and broken down. The carbon atoms start to crystallize, layer by meticulous layer, forming a diamond that’s pure, beautiful, and almost indistinguishable from its mined counterpart.

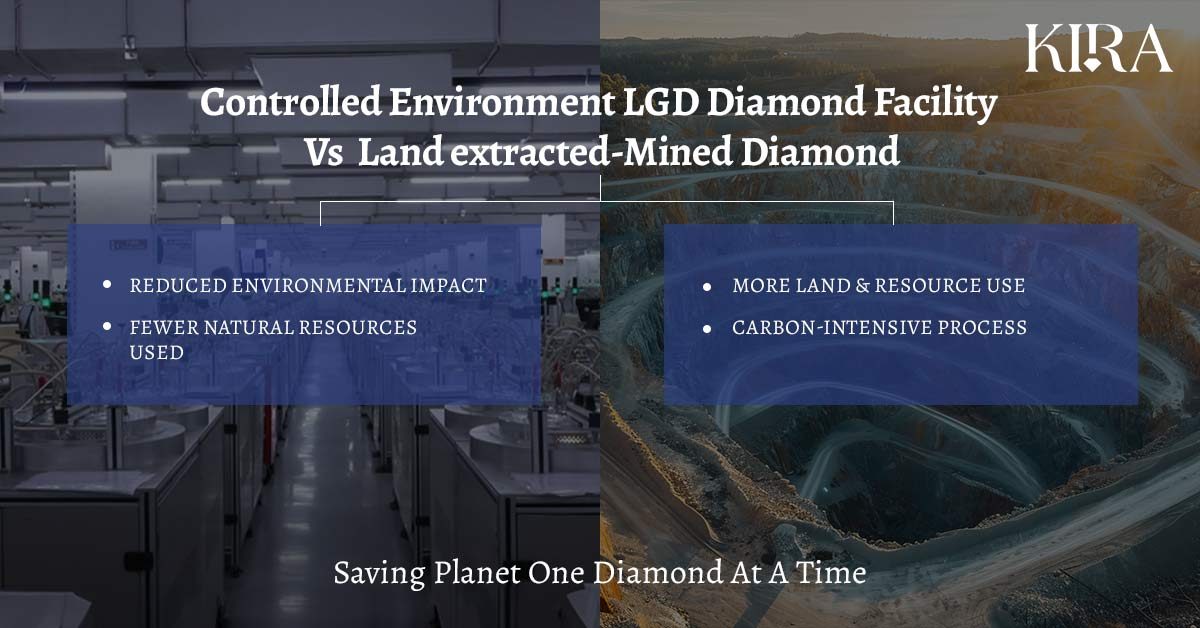

The perks of the CVD process? Well, apart from creating diamonds with fewer impurities, it’s also more eco-friendly. There’s no mining, no disruption of ecosystems, and no mountains blasted away. Just pure innovation.

Crafting for Quality: Precision Cutting and Shaping

Cutting: Where Artisan Meets Precision Technology

Cutting a diamond is where artistry truly meets technology. At Kira, we know that the cut is the most critical factor in determining a diamond’s sparkle. Our highly skilled artisans use cutting-edge machinery to shape diamonds into stunning cuts: round, pear, cushion—you name it.

Each artisan undergoes rigorous training to perfect the art of diamond cutting, ensuring that each piece reflects the highest standards. We’ve mastered producing diamonds ranging from 0.18 carats to over 10 carats in various shapes to meet the unique needs of our B2B customers.

Polishing: Perfecting the Sparkle

Once a diamond is cut, it moves on to polishing, where we refine each facet to make the stone come alive. This step involves our artisans carefully polishing every angle to ensure optimal light reflection. The result? Diamonds that catch the eye and refuse to let go.

It’s not just a matter of buffing. Polishing is where the diamond’s true beauty emerges, turning a rough gem into an object of desire. We pride ourselves on our attention to detail, and it shows in the brilliance of our final products.

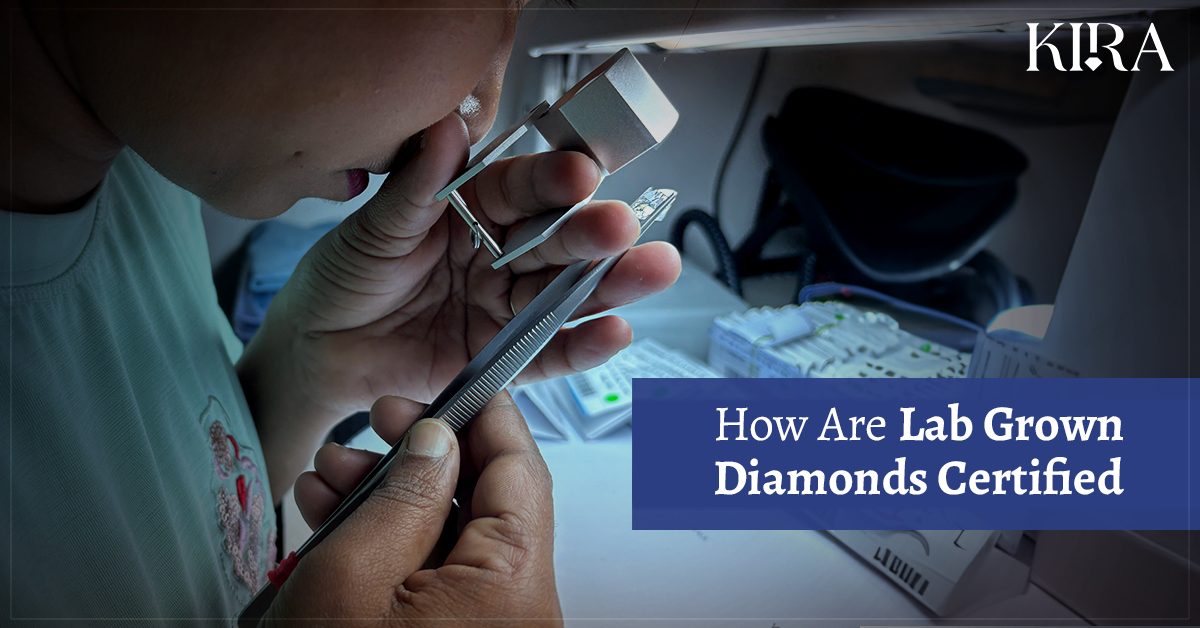

Advanced Certifications for Guaranteed Quality

Kira’s Rigorous Certification Process

Every Kira diamond undergoes stringent quality checks to meet international standards. Whether it’s the International Gemological Institute (IGI) or the Gemological Institute of America (GIA), our diamonds come certified to ensure that they meet the rigorous demands of our B2B partners. Why does certification matter? In one word: trust. For businesses, certification is not just a formality; it’s the backbone of transparent and credible transactions.

Sustainability at Kira: The Planet-Friendly Approach

Commitment to Eco-Friendly Practices

Sustainability isn’t a buzzword for us—it’s a way of doing business for us. Our facility runs on solar power, reducing our carbon footprint significantly. Unlike traditional mining, which can leave entire ecosystems scarred and broken, our lab-grown diamonds are kinder to the planet. There’s no digging, no wasted water, no ecological destruction—just pure, guilt-free beauty.

Looking for loose diamonds?

Looking for loose diamonds? Discover Kira, the world’s largest CVD diamond producer, offering 150,000 polished carats monthly from our state-of-the-art Surat facility. Specializing in stunning fancy-colored diamonds—yellow, pink, blue, and green—in a variety of shapes, including Round, Oval, Radiant, Emerald, Pear, Princess, and Marquise. With 3000+ CVD machines and a reliable global delivery service, we can fulfill orders of any size. Join our established end-to-end supply chain and experience the quality and variety that Kira has to offer.

Kira’s 7 Ps for Sustainability and Innovation

Ever wondered what guides our sustainable practices? In our case, it’s the 7 Ps: Pricing, Practical, Progressive, Planet-Friendly, Popularity, Perfection, Potential. These principles aren’t just corporate jargon; they are actionable steps that steer our entire production process. For instance:

| Principle | Actionable Step |

|---|---|

| Planet-Friendly | Powered by solar energy |

| Perfection | Rigorous quality checks for every diamond |

| Practical | Streamlined processes |

These Ps are at the heart of every decision we make, from the energy we use to the materials we choose.

Kira’s Finished Product: Jewelry-Ready Diamonds and Beyond

B2B Solutions: Serving Wholesalers and Retailers

When the final product is ready, it’s not just a diamond—it’s a work of art, certified and crafted to fit a variety of needs. We offer certified and non-certified loose diamonds, custom orders, and even ready-made jewelry. Whether it’s a small boutique looking for unique pieces or a large retailer needing a bulk order, our inventory of over 40,000 diamonds in New York City has you covered.

Fancy Colored Diamonds for a Distinctive Touch

Looking for something with a splash of color? Kira’s got that, too. From radiant yellows to romantic pinks and serene blues, our fancy-coloured diamonds bring a distinctive touch to any collection. They’re perfect for retailers looking to stand out and offer their customers something truly unique.

Conclusion

Kira isn’t just about producing diamonds; it’s about setting new standards in sustainability, craftsmanship, and quality. From the seed to the final polished gem, our process embodies the best of technology and tradition, catering to the diverse needs of B2B partners across the globe. Ready to experience the Kira difference? Explore our collection and see why our diamonds aren’t just made—they’re crafted.