The Secret Behind the Growing Popularity Of CVD Diamonds In The Jewelry Industry

The allure of lab-grown diamonds is rapidly gaining momentum, particularly with the surge in their popularity. As consumers become more environmentally and ethically conscious, lab-grown diamonds become a compelling alternative to traditionally mined diamonds. These diamonds are produced through sophisticated technology in controlled laboratory environments, mimicking the natural diamond growing process. This includes diamonds created using Chemical Vapor Deposition (CVD) technology. Over the years, CVD technology has gained notable attention across the globe. This sustainable and ethical option resonates with modern consumers seeking responsibly produced luxury goods. The rising demand for lab-grown diamonds reflects a shift towards more environmentally friendly and socially responsible practices in the jewelry industry.

What Are The Different Types Of Lab Grown Diamonds?

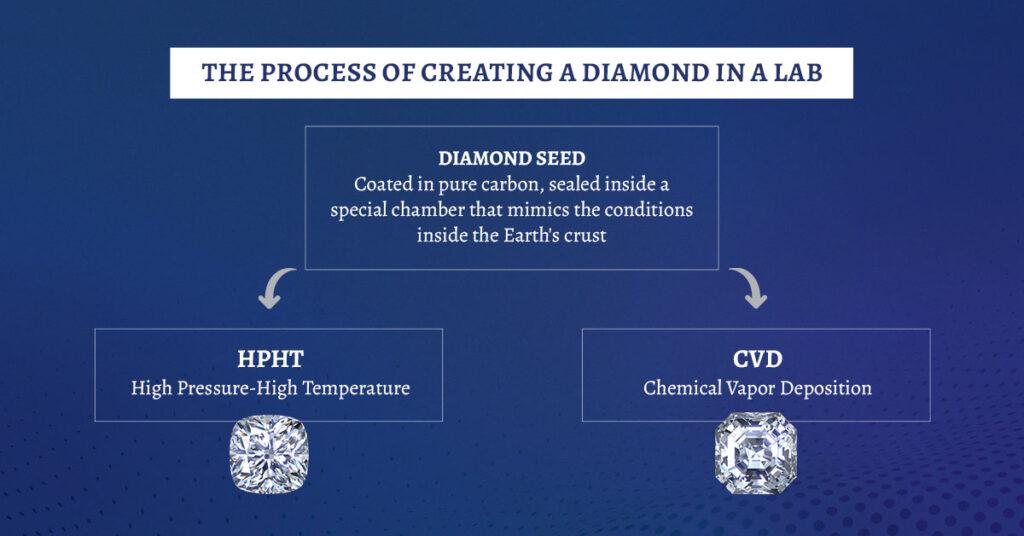

A wide range of lab-grown diamonds is produced to meet different market demands and applications. Following are two prominent methods used for diamond production.

- Chemical Vapour Deposition (CVD): This method involves the deposition of carbon atoms onto a substrate in a vacuum chamber using a carbon-rich gas like methane. The carbon atoms then crystallize to form diamond structures. CVD is a popular method for creating lab-grown diamonds due to its scalability and relatively low cost. CVD offers several advantages over other methods of diamond synthesis, such as high purity, control over diamond properties, and the ability to produce large diamonds. It’s widely used in both industrial applications and research laboratories for creating diamonds used in electronics, cutting tools, and jewelry.

- High-Pressure High-Temperature (HPHT): In this method, a small diamond seed is placed into a high-pressure, high-temperature environment along with a carbon source. The seed acts as a catalyst for the growth of a larger diamond crystal as carbon atoms are forced to crystallize around it. HPHT diamonds are known for their high clarity and can be created in various colors. HPHT is one of the earliest methods used for synthetic diamond production and is still widely utilized today. It’s known for producing diamonds with high clarity and quality, suitable for use in jewelry, cutting tools, and industrial applications. However, compared to CVD, HPHT is generally more expensive and requires more energy, but it can produce larger individual diamonds.

Get Your Kira Mobile Apps Now On The App Store & Google Play!

Get Your Kira Mobile Apps Now On The App Store & Google Play!

How Are CVD Diamonds Made?

Making CVD (Chemical Vapor Deposition) diamonds involves several steps. First, a small, flat substrate, typically a thin slice of diamond, is placed in a vacuum chamber. The chamber is then filled with carbon-rich gas, such as methane, along with hydrogen. Next, the chamber is heated to temperatures around 800 to 1200 degrees Celsius, creating a plasma environment. This plasma breaks down the gas molecules, releasing carbon atoms. These carbon atoms then settle onto the substrate, gradually building up layers of diamond material. The process continues for several hours or days, depending on the desired size and quality of the diamond. Finally, once the desired thickness is achieved, the diamond is carefully removed from the chamber and undergoes cutting, polishing, and finishing processes to create the final CVD diamond product. This method allows for the precise control of diamond growth and the production of high-quality synthetic diamonds for various industrial and jewelry applications.

Making CVD (Chemical Vapor Deposition) diamonds involves several steps. First, a small, flat substrate, typically a thin slice of diamond, is placed in a vacuum chamber. The chamber is then filled with carbon-rich gas, such as methane, along with hydrogen. Next, the chamber is heated to temperatures around 800 to 1200 degrees Celsius, creating a plasma environment. This plasma breaks down the gas molecules, releasing carbon atoms. These carbon atoms then settle onto the substrate, gradually building up layers of diamond material. The process continues for several hours or days, depending on the desired size and quality of the diamond. Finally, once the desired thickness is achieved, the diamond is carefully removed from the chamber and undergoes cutting, polishing, and finishing processes to create the final CVD diamond product. This method allows for the precise control of diamond growth and the production of high-quality synthetic diamonds for various industrial and jewelry applications.

Why Are CVD Diamonds Gaining Popularity In The Diamond Jewelry Space?

- Ethical and Sustainable Sourcing: These diamonds offer an ethical and sustainable sourcing alternative created in controlled laboratory environments. This eliminates the environmental and social concerns associated with traditional diamond mining, such as habitat destruction and unethical labor practices.

- Cost-Effectiveness: CVD diamonds are often less expensive to produce than mined diamonds, making them more accessible to a broader range of consumers. Moreover, the CVD process allows for precise control over the growth of diamonds, including color, clarity, and size, enabling jewelry designers to create unique and personalized pieces tailored to individual preferences.

- Customization: Moreover, the CVD process allows for precise control over the growth of diamonds, including color, clarity, and size, enabling jewelry designers to create unique and personalized pieces tailored to individual preferences.

- Consistency and Quality: CVD diamonds can be produced with consistent quality and characteristics, free from the natural flaws and impurities found in mined diamonds. This ensures high-quality diamonds suitable for use in jewelry.

- Innovation and Technology: Lastly, technological advancements in the CVD diamond industry continue to innovate and develop new techniques, allowing for the production of larger diamonds, improved colors, and enhanced quality, further contributing to their growing appeal in the lab grown diamond jewelry market.

Future Trends and Concerns in the CVD Diamond Jewelry Industry

As CVD (Chemical Vapor Deposition) diamonds gain traction in the jewelry industry, several trends and concerns shape their future:

- Price Concerns and Market Share: While the decreasing production costs of CVD diamonds may raise apprehensions among consumers, it simultaneously opens avenues for widening market accessibility and augmenting the market share of CVD diamonds.

- Consumer Perception and Branding: Another key concern among consumers is the perception of CVD diamonds being “fake” or inferior to natural diamonds. Such concerns can be addressed with adequate robust branding and educational efforts. These efforts aim to underscore the ethical, environmental, and quality advantages inherent in CVD diamonds as compared to their mined counterparts.

- Regulatory Standards: The establishment of universally accepted regulations and certifications, such as those provided by the International Gemological Institute (IGI) or the Gemological Institute of America (GIA), plays a pivotal role in upholding consumer confidence regarding the authenticity and quality of CVD diamonds.

- Sustainability and Ethical Sourcing: Ongoing efforts in sustainable manufacturing and responsible sourcing directly address concerns regarding the environmental impact and ensure ethical practices throughout the entire supply chain of CVD diamonds.

- Innovation and Technology: Continuous progress in technological processes for CVD diamond production contributes to enhancements in quality, size, color, and consistency. This ongoing innovation addresses concerns related to variability in synthetic diamond quality, fostering increased acceptance and appeal within the lab grown diamond jewellery market.

Looking for loose diamonds?

Looking for loose diamonds? Discover Kira, the world’s largest CVD diamond producer, offering over 250,000 certified lab grown diamonds ranging from 0.18 to 10+ carats, all sourced from our state-of-the-art Surat facility. Specializing in stunning fancy-colored diamonds—yellow, pink, blue, and green—in a variety of shapes, including Round, Oval, Radiant, Emerald, Pear, Princess, and Marquise. With 3000+ CVD machines and a reliable global delivery service, we can fulfil orders of any size. Join our established end-to-end supply chain and experience the quality and variety that Kira has to offer.

How Should You Buy CVD Diamond Jewelry And From Where?

People who prioritize ethical sourcing and sustainability often choose CVD diamonds due to their conflict-free origins and environmentally friendly production process. Additionally, individuals seeking high-quality diamonds at competitive prices find value in CVD jewelry. In other words, anyone who values ethical sourcing, quality, affordability, and customization may consider purchasing CVD diamond jewelry. It is important to check the key certifications like the International Gemological Institute (IGI) or the Gemological Institute of America (GIA) to verify the quality of the diamonds before making the purchase. Apart from this, you can also consider your preferences and budget, and purchase from trustworthy wholesalers to ensure a positive and satisfying shopping experience.

Conclusion

In recent years, CVD diamond jewelry has offered a compelling alternative to traditional diamonds, with its ethical sourcing, cost-effectiveness, customization options, consistent quality, and technological advancements. These diamonds are gaining traction due to their ethical sourcing and low carbon footprint. CVD diamond jewelry provides an appealing choice for buyers looking for both quality and ethical sourcing. As the industry continues to innovate and refine production techniques, CVD diamond jewelry is poised to become an even more prominent and accessible choice for consumers worldwide. Over the years, we’ve established ourselves as a key player in the CVD diamond business, providing an extensive range of high-quality synthetic diamonds to fulfill a variety of client demands and preferences. With the growing popularity of CVD diamonds, we believe Kira lab grown diamond companies in india and USA will have a critical role to play in the near future.